‘Lean’ is almost a movement, it’s become a philosophy that has applications in many spheres of business. The concept of Lean is essentially about eliminating waste from your business processes. Its origins are in manufacturing with the Toyota Motor Company, but the principles of Lean have spread and found application across myriad areas of business.

One of those, is the area of business innovation. Lean has been most notably promoted and publicized as an innovation methodology by Eric Ries and his mentor Steve Blank. They came up with the application of Lean to innovation and have written a number of books on the subject.

Ries started and ran a successful company himself. He realized that what he was doing with that startup was applying the principles of Lean to his business process. Together with Blank they went on to discuss and document how the lean principles can be successfully applied to innovation.

The History of ‘Lean’

Just after the Second World War, Toyota had a problem. Restrictions in the marketplace meant that Toyota had to produce small quantities of many varieties of cars and trucks under conditions of low demand, while facing competition from the mass production manufacturers in Europe and the United States.

Toyota had started life as a textile company. The success of the Toyoda Automatic Loom Works was based on the development by Sakichi Toyoda of sophisticated automated power looms for weaving textiles. The patent for the looms was sold to Platt Brothers, the leading manufacturer of spinning and weaving equipment, for £100,000. In 1930 this money was used to start the Toyota Motor Company, which struggled in its early years.

In 1950, Taiichi Ohno had become plant manager. He was given the mission of improving Toyota’s manufacturing process so that it equalled the productivity of the Ford Motor Company. Mr Ohno had been a manager at the weaving plant of Toyoda Spinning and Weaving before he was made production manager at the car factory. In his previous job, he saw that, as a result of smart automation, one woman could run a large number of weaving machines. He applied similar principles to automotive manufacturing. He documented these principles, and Toyota’s underpinning philosophy, in a short book, Toyota Production System.

The essence of the Toyota Production System, which later gave birth to the term Lean Manufacturing, is a systemic method for the elimination of waste ("Muda") within a manufacturing process. Lean also takes into account waste created through overburden ("Muri") and waste created through unevenness in workloads ("Mura").

- Muda is anything that takes time but does not add value to your customer

- Muri – overburdening people results in safety and quality problems; overburdening equipment causes breakdowns and defects

- Mura – unevenness; heijunka is levelling out the work schedule; behaving more like the tortoise rather than the hare

Working from the perspective of the client who consumes a product or service, "value" is any action or process that a customer would be willing to pay for. Essentially, Lean is centered on making obvious what adds value by reducing everything else. As Mr Ohno says in the foreword to his book: “All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing that time line by removing the non-value-added wastes”.

“The key to the Toyota Way and what makes Toyota stand out is not any of the individual elements…..But what is important is having all the elements together as a system. It must be practiced every day in a very consistent manner – not in spurts”

— Fujio Cho, President of Toyota Motor Company, 2002

Lean has now caught on in many areas of business, including construction, services, integration, higher education, accounting and Lean Six Sigma, the combination of lean and six sigma approaches.

Applying Lean to Business Innovation

It was Eric Ries and his mentor, Steve Blank who led the charge when it comes to applying lean principles to innovation. Ries documented his journey to Lean, and its principles and practice in his 2011 book The Lean Startup. Steve Blank and Eric Dorf have written The Startup Owner’s Manual: The Step-by-Step Guide for Building a Great Company, which guides you through the Lean Startup process. Ries wrote a later book, The Startup Way, which he says “owes its title to Jeffery Liker’s magisterial The Toyota Way”. This shows how the Lean Startup system can become a system of entrepreneurial management that can lead organizations of any size from any industry to growth and long-term impact.

Eric Ries had a number of successes and failures as an entrepreneur and came to realize that startup success can be engineered by following the right process, that entrepreneurship is a kind of management. He was successfully applying what are now recognized as many of the principles of lean innovation, which ran counter to the then perceived wisdom about entrepreneurship. He began to look outside entrepreneurship for ideas that would help him understand his experience. He found these ideas in Lean Manufacturing and applied them to create the framework that he would document in The Lean Startup.

The Lean definition of a startup is

- A temporary organization

- Designed to search for a repeatable and scalable business model

- Designed to fail fast and be continually learning. By failing fast, you know quickly if your idea is no good

Startups are not smaller versions of large companies. The ones that succeed go from failure to failure, all the while adapting, iterating on, and improving their initial ideas as they continually learn from customers. While existing companies execute a business model, start-ups look for one. However, you can have lean startup initiatives within large companies, and many large companies now have innovation incubators that follow the Lean Startup method. Indeed, many have incorporated the Startup Way into their management system.

The Four Pillars of Lean Startup

The Four Pillars of the Lean Startup method are:

Build-Measure-Learn

Quickly build something that you can try out on potential customers; measure its acceptability and value to its intended audience and learn from what you’ve measured

Build a Minimum Viable Product

Build something that’s good enough to try on customers, no frills, probably not much error recovery. Build it quick and fast; get it out to early adopters; think big; start small

Conduct an Experiment and Collect Relevant Metrics

Create a hypothesis about the product or market; create experiment(s) to try out your hypothesis; measure the experiment’s outcome to validate or disprove hypothesis.

A key part of this measurement is what the method calls Innovation Accounting, which focuses on how entrepreneurs can maintain accountability and maximize outcomes by measuring progress, planning milestones, and prioritizing. This is different from traditional accounting.

Another key part is Validated Learning. This is defined as a process in which one learns by trying out an initial idea and then measuring it to validate its effect. Each test of an idea is a single iteration in a larger process of many iterations whereby something is learnt and then applied to succeeding tests.

Persevere or Pivot

Find the sweet spot of your product. Your metrics will tell you if you should keep going with your original idea or “pivot” and turn in a different direction.

Build – Measure – Learn

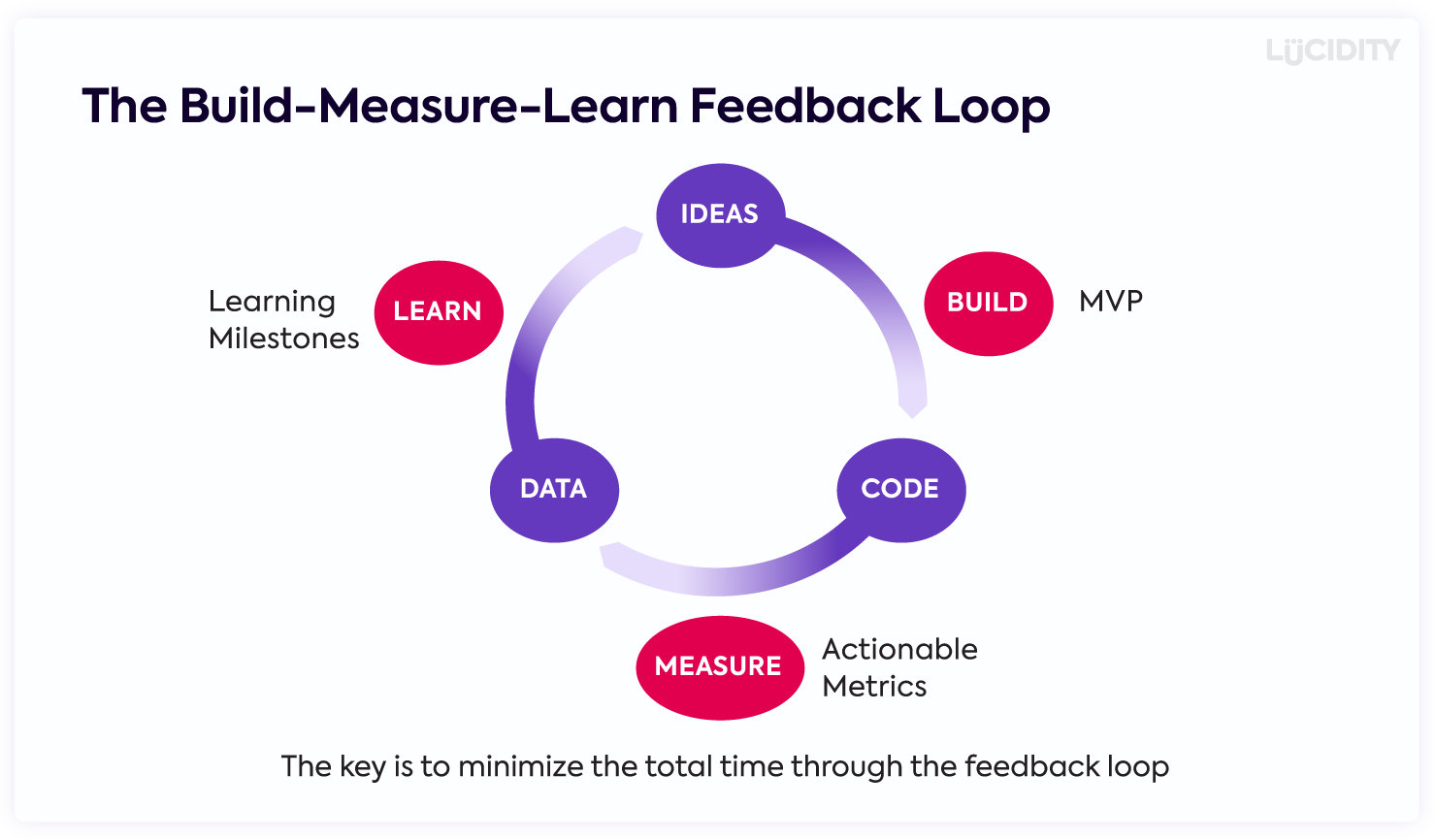

Below is an illustration of the Build-Measure-Learn iterative feedback loop

Build-Measure-Learn is the core part of the lean startup methodology that explains what we should do between the phases of Idea -> Build -> Code -> Measure -> Data -> Learn. In other words, it is a loop process of turning ideas into products, measuring customers’ reactions and behaviors against built products, and then learning whether to persevere with or pivot the idea; this process repeats over and over again. If you pivot to a new idea, you create a new baseline and start the iteration process from there.

The MVP

It’s worth remembering, an MVP does not have to be a physical product or a software offering. Zappos is an American online shoe and clothing retailer. Their hypothesis, back in 1999, was that people were ready to buy shoes online. Nick Swinmurn, the founder, took pictures of the inventory in local shoe stores and posted the pictures online on Shoesite.com. If a customer wanted a shoe, he bought it from store and sent it to the customer. In this way, he validated his hypothesis, then built the business. Zappos was acquired Amazon in 2009 for $1.2bn.

Dropbox allows you to synchronize your files between PCs, laptops, mobile phones etc. Drew Houston thought it would be too hard and time consuming to build a prototype in order to convince potential investors, so he and his co-founder made a 3 minute video.

Steve Blank’s Customer Development Process

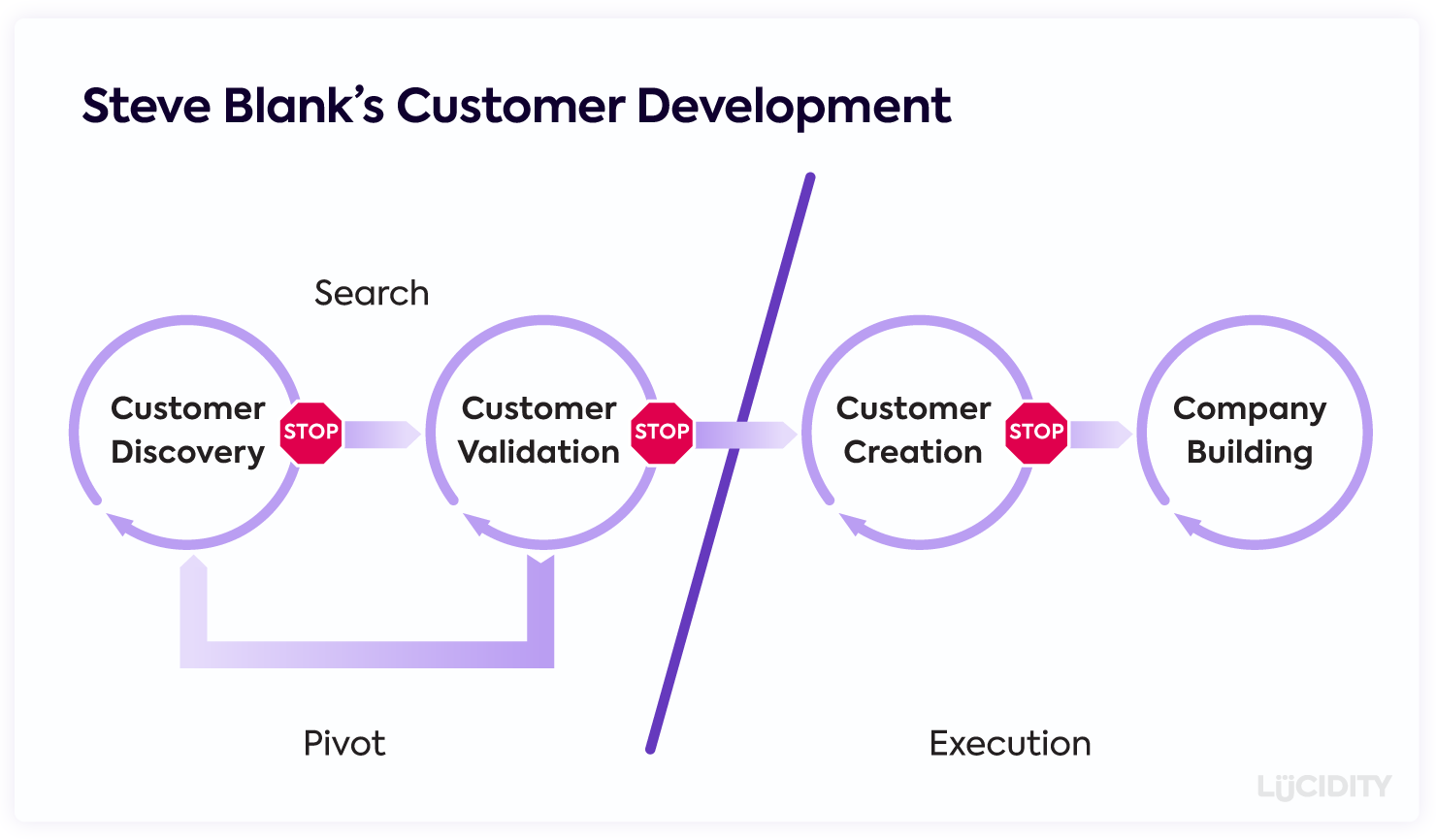

The next thing that lean startup practitioners do is what Steve Blank calls, in this Harvard Business Review article, “Get out of the Building” or what Toyota call “genchi gembutsu” – “go and see for yourself”. Steve had documented what he called a Customer Development Process, embodying Lean Startup principles:

- Customer Discovery – translate ideas into business model hypotheses, test assumptions, create a Minimum Viable Product

- Customer Validation – continue to test all other hypotheses and try to validate customer interest through early orders or product usage; if no interest, startup can “pivot” by changing one or more hypotheses

- Customer Creation – product has been iterated enough so that it is refined enough to sell; ramp up marketing and sales

- Company Building – transition from startup mode into an established company

Agile Development

The third enabler of the Lean Startup model is agile development, which has its origins in agile software development. This is a group of software development methods in which requirements and solutions evolve through collaboration between self-organizing, cross-functional teams, and has become the predominant way of developing software. Agile promotes adaptive planning, evolutionary development in small increments, early delivery, continuous improvement, and encourages rapid and flexible response to change.

Agile development doesn’t apply only to software. In his book, Eric Ries gives the example of SGW Designworks. Their specialty is rapid production techniques for physical products. They were engaged by a client who had been asked to build a ruggedised portable complex x-ray machine to detect explosives etc. at border crossings and in war zones. SGW designed prototypes with CAD (Computer Aided Design). Three days after the design was agreed by the client, they delivered physical prototypes. The parts were machined in aluminum directly from CAD using computer numerical control and hand assembled by the SWG team. A second iteration was done in 5 days.

Actionable Metrics

Another important aspect of lean innovation championed by Ries is the focus on Actionable Metrics. These are metrics that can lead you to informed business decisions and subsequent action, and are in contrast to ‘vanity metrics’ – measurements that give “the rosiest picture possible” but do not accurately reflect the key drivers of a business.

However, vanity metrics for one company may be actionable metrics for another. For example, a company specializing in creating web-based dashboards for financial markets might view the number of web page views per person as a vanity metric – their revenue is not based on number of page views. However, an online magazine with advertising would view web page views as a key metric since page views are directly correlated to revenue.

A typical example of a vanity metric is ‘the number of new users gained per day’. While a high number of users gained per day seems beneficial to any company, if the cost of acquiring each user through expensive advertising campaigns is significantly higher than the revenue gained per user, then gaining more users could quickly lead to bankruptcy. Be honest and realistic about your metrics!

Validated Learning

Validated learning, mentioned earlier, is a term coined in the lean startup scene, but it can be applied universally. Validated learning is defined as a process in which one learns by trying out an initial idea and then measuring it to validate the effect. Each test of an idea is a single iteration in a larger process of many iterations whereby something is learnt and then applied to succeeding tests.

Validated learning is especially popular on the Internet, where analytics software can track visitor behavior and give accurate statistics and insight on how website features work in reality. Validated learning can, however, be applied to anything; one just needs to be innovative on what to use as metrics.

Typical steps in validated learning:

- Specify a goal

- Specify a metric that represents the goal

- Act to achieve the goal

- Analyze the metric – did you get closer to the goal?

- Improve and try again

The Pivot

Finally, a pivot is a “structured course correction designed to test a new fundamental hypothesis about the product, strategy, and engine of growth”.

A notable example of a company employing the pivot is Groupon; when the company first started, it was an online activism platform called The Point which was intended to organize people around some sort of cause or goal. After receiving almost no traction, the founders decided to pivot in order to focus entirely on group buying. Their first deal was a two-pizzas-for-the-price-of-one offer at Motel Bar, a restaurant on the first floor of their building in Chicago. Even though they only got 20 redemptions, they considered their hypothesis validated. Three years later, Groupon would grow into a billion-dollar business.

The Lean Startup has led to a whole Lean Startup movement. Eric Ries and others created an annual technology conference called Startup Lessons Learned which subsequently changed its name to the Lean Startup Conference. There are Lean Startup meetups in cities around the world. The Lean Startup Machine created a new spin on the lean startup meetups by having attendees start a new company in three days.

Manage your innovation strategy with the right tools

Build, communicate and execute your strategy all in one place. Book a personal demo and we'll show you how.